- Regularly inspect castors and wheels for wear and tear: Look for signs of damage such as cracks, chips, or worn treads and replace them as needed.

- Keep castors and wheels clean: Regularly clean and sanitize castors and wheels to prevent the build-up of debris and bacteria.

- Use the right lubricant: Use a lubricant specifically designed for use on castors and wheels to keep them running smoothly and reduce friction..

- Use the right size and weight capacity: Be sure to select castors and wheels that are the right size and weight capacity for the equipment or surface they will be used on.

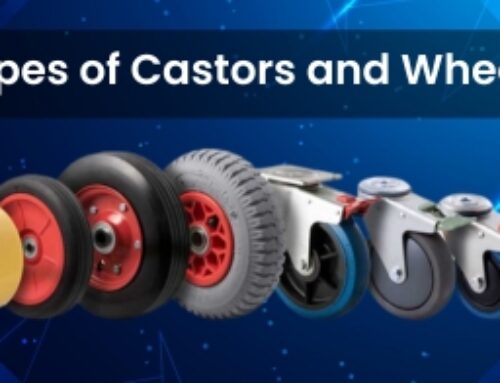

- Use the right type of castor or wheel: Choose the right type of castor or wheel for the specific application, such as a heavy-duty castor for a load-bearing application or a swivel castor for maneuverability.

- Secure loose fittings: Make sure that all fittings, such as nuts and bolts, are properly tightened to prevent movement or wobbling.

- Keep them in good alignment: Check that the castors or wheels are in proper alignment to prevent uneven wear and tear.

- Use locking mechanisms: Use locking mechanisms to prevent unwanted movement or rolling of equipment when it is not in use.

- Take care when moving heavy loads: Be sure to use proper lifting and moving techniques when handling heavy loads to prevent damage to the castors and wheels.

- Store them properly: When not in use, store castors and wheels in a clean, dry place to prevent damage or contamination.

Leave A Comment