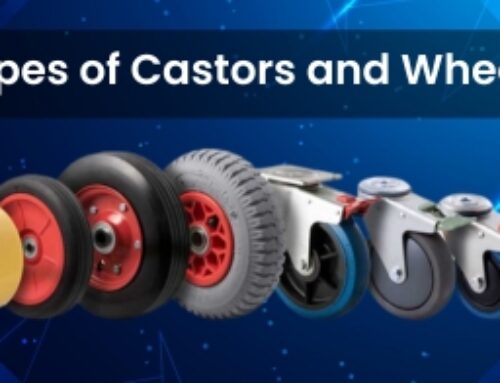

What is the Difference between Wheels and Castors?

In the materials handling industry, it is necessary to be precise while searching for a specific item. Therefore, knowing the exact product name is crucial. One of the most common misconceptions is the difference between wheels and castors. Many people may not understand what a castor is, but when they see one, they may refer to it as a wheel.

However, castors are more than simply wheels! Many people often mention wheels and castors interchangeably. That’s why it’s important to know the difference between these two terms.

Wheels vs. Castors

You may be wondering, “What is a castor wheel?” or “Is a castor a wheel?” or if it is only an industry word. The phrases “wheels” and “castors” are frequently used synonymously to describe rolling equipment, causing many people to believe they are the same. Although both wheels and castors are rolling devices, they differ in several ways. Let us discuss more wheels and castors, and how they vary so that you can choose the right rolling device for your specific application.

What is a wheel?

Everyone is acquainted with the wheel. It is a spherical device with a hole in the middle for use as a shaft. One may characterise it as a broader or narrower circular cylinder that rotates on an axle, similar to a car’s wheels. The wheel has various mechanical applications.

Wheels have been around for a very long time and were discovered in artefacts from 4500 BC. The wheel has undergone significant development over the years and has altered the way we live, work, and create. These circular devices are meant to roll when subjected to a force and they are considered primary machines in levers, wedges, axles, and pulleys. Wheels come in a variety of sizes and materials, including rubbers and polyurethane (PU).

What are castors?

While wheels have been in use for many years, it has been roughly 150 years since the invention of the castor. Castors are wheeled rolling devices that are attached to a piece of equipment or apparatus to make it mobile. They can be found on industrial machinery, office seats, shopping carts, and more.

Castors typically comprise a wheel within a metal frame. They are installed utilising fasteners that attach the frame to a specific item. Every castor has a wheel and the wheel is positioned within a metal frame, where it may roll when subjected to force.

Below are some of the most predominant varieties of castor:

- Rigid throwers

- Rotating castors

- Medical castors

- Levelling castors

- Rotacastors

- Industrial castors

A castor is an assembly of a wheel and a bracket, sometimes known as a “fork” or “yoke,” that holds the wheel in place. Therefore, when you want to replace the “wheel” at the base of your chair or cart, you will have to replace the castor assembly.

Castors are available in two distinct styles:

- Plate Mounted – Plate-mounted castors have a flat bracket with mounting holes that allow them to be mounted flush against another flat surface.

- Stem Mounted – Stem-mounted castors are those without a smooth surface. Instead, they have a threadedpintel or a spring retention clip that may thread or otherwise latch onto the mounting item.

Types of Castors

Castors are becoming sought-after devices due to their flexibility and ease of use. There are different types of castors based on the type and degree of movability, such as:

- Spinning castors – These allow the wheel to rotate 360 degrees while under load. The swivel circles around the pivot point, and this motion is called “cast” in that little circle, hence the name ‘castor.’. This castor function makes it much easier to transport oversized items and navigate tight corners in a warehouse. Swivel castors have different variants, including locking castors, plate castors, stem castors, and kingpin-less castors. The General Duty castor from Shepherd is an excellent example of a swivel castor.

- Standard Swivel Castors – This zinc-plated castor is RoHS-compliant and features nickel-plated kingpins for a smoother swivel. This castor is commonly used for material-handling equipment, industrial equipment, and furniture transportation. Although the outside of the castor is nickel-plated, you can select the material for the wheel itself. The general duty castors come with different options for wheel material, such as soft rubber, polyolefin, hard rubber and steel.

All general-duty castors feature a 13/16″ thread width, and the swivel radius varies based on castor size. Your wheel diameter options can be 2, 2.5, 3, and 4 inches and each castor can support between 80 and 120 pounds. The bigger the wheel, the more weight it can support.

Apart from spinning castors and standard swivel castors, there are also Ball Bearing and Kingpinless castors. These types of castors offer increased load capacity and shock absorption. These may be found on the Wicke website.

- Rigid Castors – Rigid castors, often referred to as fixed castors, consist of a wheel positioned between the legs of a non-rotating bracket. Because of this, rigid castors are well-suited for applications in which you must transport materials forwards and backwards in a straight line, but not around corners. Rigid castors are more durable than swivel castors and can support higher weight capabilities due to the absence of a swivel portion vulnerable to tangential stresses. The Regent Stiff Top Plate Model perfectly illustrates a rigid castor.

Regent Rigid Top Plate Model

This popular rigid castor has a zinc finish and is RoHS-compliant. It has multiple raceways with ball bearings and an octagonal washer on a threaded stem. This variant’s raceways have been heat-treated for greater wear and resistance. This castor is appropriate for medical equipment, carts, furniture, and institutional equipment because of its limited movement.

The regent rigid top plate model’s castor wheels are available in different materials, including hard rubber, polyurethane, polyolefin, soft rubber, and TPR. The width of the castor wheel thread is 13/16″ or 15/16” and the wheel diameter options are 3, 4, and 5 inches. Depending on the size of the wheel, the swivel might range from 2 12, 3 7/16, and 4 1/8 inches. Each castor can hold between 110 and 160 pounds of weight.

The majority of rigid castors provide braking options. This model is available with either a friction brake or a thread lock brake. If the brake is not standard and you would like one, it can be arranged or produced.

Wheels or Castors – Which one is Right for You?

Ball castors and wheels- while they both serve the purpose of transporting heavy equipment or materials, there are distinct differences between them. Wheels are less complex than castors and consist of circular objects that can rotate when force is applied. On the other hand, castors are more complicated and consist of spherical objects that may roll when subjected to a force. Castors incorporate a metal frame that enables them to be attached to another object.

Castors are available in more varieties than conventional wheels due to their metal frames, such as swivelling castors which can pivot from side to side. Wheels are more challenging to install than castors since wheels cannot be attached directly to a surface. Instead, a frame is required for the attachment, which is where castors come in. Castors have a built-in frame that makes them easier to attach to things. The frames are commonly constructed of stainless steel or aluminium which allows for simple attachment to things.

Wicke at Your Service – Australia’s Trusted Industrial Wheels and Castor Supplier

Are you looking for wheels and castors in Australia? Wicke is the perfect destination for you. We are one of the largest producers of industrial wheels, tyres, axles, swivel castors, and fixed castors. Accordingly, we provide a wide range of wheels and castors to meet the needs of various industries.

20 years of industry experience have made us experts in industrial castor wheels, including heavy-duty roller wheels, steel castor wheels, swivel castor wheels, and more. Our team is always ready to assist you with the best possible service. You can contact our customer service staff to discuss your requirements or explore our website to learn more about what we offer.

Call us on (02) 8764 3724 or write to us at sales@wickeau.com.au for more information.

Leave A Comment