Durability: The castors and wheels used in medical equipment and furniture need to be sturdy and durable to support the weight and usage demands

When it comes to medical equipment and furniture, durability is a critical factor to consider when choosing castors and wheels. The medical industry requires high-quality and reliable equipment, and castors and wheels play a crucial role in ensuring the durability and longevity of these products.

Materials such as high-grade plastics, stainless steel, and other metals are often used in the manufacture of castors and wheels for medical equipment and furniture.

Another important consideration when it comes to durability is the design and construction of the castors and wheels .Wicke castors and wheels with reinforced frames and double ball bearings can offer increased stability and durability, making them better suited to the

demands of medical equipment and furniture.

Regular maintenance and inspection of castors and wheels can also help to ensure their durability and longevity. This includes regular cleaning and lubrication, as well as regular checks for signs of wear and tear or damage.

In conclusion, durability is a critical factor to consider when choosing castors and wheels for medical equipment and furniture. By selecting Wicke castor and Wheels high-quality materials and well-designed products, and by following a regular maintenance routine, it is

possible to ensure that castors and wheels provide the necessary support and durability to meet the demands of the medical industry.

Here are some key factors to consider when evaluating the durability of castors and wheels:

- Load capacity: One of the most important factors to consider when selecting castors and wheels is their load capacity. This is the maximum weight that the castor or wheel can support without causing damage or failure. It is important to choose castors and wheels with a load capacity that exceeds the weight of the equipment they will be supporting.

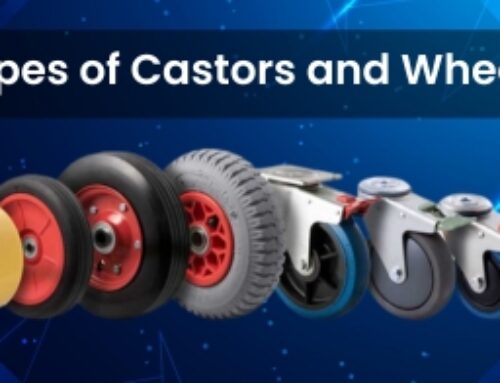

- Material: The material used to manufacture castors and wheels plays a significant role in their durability. Steel and aluminum are both strong, durable materials that are resistant to damage from impact and wear. Polyurethane and nylon are also popular materials for castors and wheels because they are abrasion-resistant and can withstand exposure to chemicals and oils.

- Bearing type: The type of bearing used in castors and wheels can impact their durability. Roller bearings are more durable than ball bearings and are a good choice for heavy loads and high-speed applications. Sealed bearings provide better protection against dirt and debris and are a good choice for environments with high levels of dust or contaminants.

- Braking system: Brakes can help extend the life of castors and wheels by reducing the wear and tear on the wheels. Choose castors with brakes that are easy to engage and disengage and that provide a strong, secure hold.

- Tread: The tread pattern on the wheels can impact their durability and performance. Wheels with a flat tread are best for smooth surfaces, while wheels with a crowned tread are better for rough, uneven surfaces. Harder treads are more durable and have a longer life span, while softer treads provide better shock absorption.

- Maintenance: Regular maintenance is critical to ensuring the durability of castors and wheels. Regular cleaning, lubrication, and inspection can help prevent damage and extend the life of the castors and wheels.

By considering these factors when selecting Wicke castors and wheels for manufacturing equipment, you can ensure that they are durable enough to withstand the demands of the environment, reduce the need for repairs and replacements, and ultimately improve the emciency of your operations. Regular maintenance is critical to ensuring the durability of castors and wheels. Regular cleaning, lubrication, and inspection can help prevent damage and extend the life of the castors and wheels.

Leave A Comment