“The Secret to a Smoother Manufacturing Operation: Investing in Durable Castors and Wheels”.

Require a lot of moving parts and equipment, and investing in durable castors and wheels is crucial for ensuring that everything runs smoothly. Here are some reasons why:

- Increased efficiency: When equipment can be easily moved from one area of the factory to another, it can help streamline the manufacturing process and reduce downtime. Durable castors and wheels make it easier to move large, heavy machinery or even smaller items with greater speed and ease.

- Improved safety: High-quality castors and wheels can provide greater stability and control, making it easier to move heavy loads safely without risking employee injury or equipment damage.

- Cost savings: Investing in durable castors and wheels can save money in the long run by reducing the need for costly repairs or equipment replacement due to wear and tear.

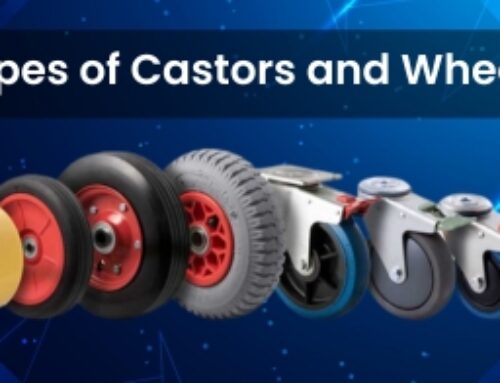

- Customizability: Castors and wheels come in a variety of sizes, shapes, and materials, allowing manufacturers to find the perfect match for their unique needs. This can help increase the functionality and versatility of equipment, making it easier to adapt to changing production requirements.

- Better sanitation: Castors and wheels made from materials like stainless steel can be more hygienic and easier to clean, making them a better choice for manufacturing environments where cleanliness and hygiene are essential.

Overall, investing in durable castors and wheels can have a significant impact on the emciency and safety of manufacturing operations. By carefully selecting the right castors and wheels for their unique needs, manufacturers can improve productivity, save money, and provide a safer working environment for their employees.

Certainly! Here are some additional points to consider when investing in castors and wheels for manufacturing operations:

- Load capacity: It is important to consider the weight of the equipment that will be supported by the castors and wheels when making a purchasing decision. Choosing castors and wheels with a higher load capacity than what is needed can help prevent premature wear and tear and improve overall safety.

- Durability: The manufacturing industry is tough on equipment, and castors and wheels are no exception. Choosing durable materials, such as heavy-duty steel or high-strength plastic, can help ensure that castors and wheels last as long as possible under harsh conditions.

- Floor surface: The type of floor surface on which castors and wheels will be used can also impact the choice of product. Harder surfaces, such as concrete, may require castors with softer wheels to prevent damage to the floor, while softer surfaces, such as carpet, may require castors with larger, firmer wheels to maintain mobility.

- Ergonomics: The design of castors and wheels can impact the ergonomics of equipment, making it easier and safer for employees to use. For example, larger diameter wheels can help reduce the amount of force required to move heavy loads, while swivel castors can help improve maneuverability and reduce the risk of injury.

- Environmental considerations: Some manufacturing processes require equipment to be used in harsh environments, such as extreme temperatures, wet or humid conditions, or exposure to corrosive substances. Choosing castors and wheels that are designed to withstand these conditions can help prevent equipment failure and reduce the need for maintenance.

By considering these factors when selecting Wicke castors and wheels for manufacturing equipment, companies can improve emciency, safety, and equipment longevity, while also reducing the need for costly repairs and replacements.

Leave A Comment